Project Description

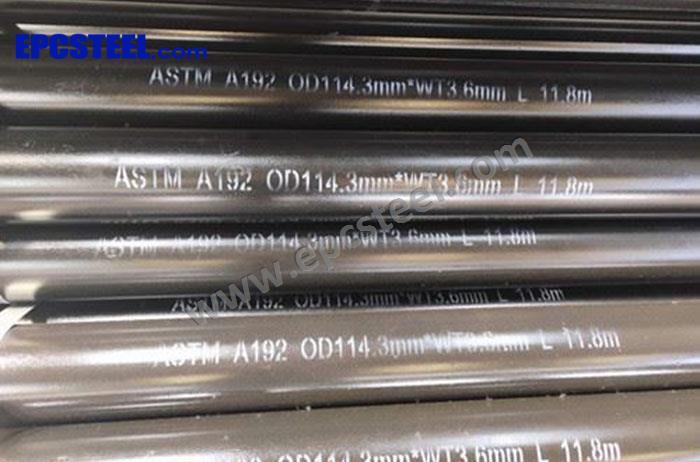

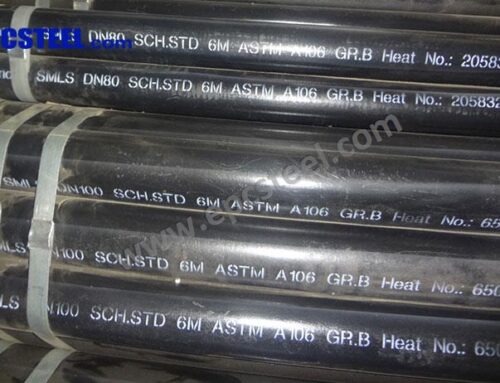

ASTM A192 seamless carbon steel boiler tubes are used in heaters, heat exchangers, refineries and other petrochemical applications with high pressure. The steel tubes shall be made by the seamless process and shall be either hot-finished or cold-finished.

Outside diameter of the ASTM A192 bolier tubes:

| Hot-Finished Seamless Tubes | Outside Diameters /mm | Permissible Variations /mm |

| OD≤101.6 | +0.4/-0.8 | |

| 101.6<OD≤177.8 | +0.4/-1.2 | |

| Cold-Finished Seamless Tubes | Outside Diameters /mm | Permissible Variations /mm |

| OD≤5.4 | ±0.10 | |

| 25.4<OD≤38.1 | ±0.15 | |

| 38.1<OD≤50.8 | ±0.20 | |

| 50.8<OD≤63.5 | ±0.25 | |

| 63.5<OD≤76.2 | ±0.30 | |

| 76.2<OD≤101.6 | ±0.38 | |

| 101.6<OD≤177.8 | +0.38/-0.64 |

Wall thickness and permissible variations of the ASTM A192 seamless carbon steel boiler tubes:

| Wall Thickness | Permissible Variations(%) | |

| OD≤101.6 | OD>101.6 | |

| WT≤2.4 | +40/-0 | N/A |

| 2.4<WT≤3.8 | +35/-0 | +35/-0 |

| 3.8<WT≤4.6 | +33/-0 | +33/-0 |

| WT>4.6 | +28/-0 | +28/-0 |

| Outside Diameter, mm | Permissible Variations(%) |

| OD≤38.1 | +20/-0 |

| OD>38.1 | +22/-0 |

Chemical Composition of ASTM A192 carbon steel tubes:

| Elements | Composition (%) |

| Carbon | 0.06-0.18 |

| Manganese | 0.27-0.63 |

| Phosphorus, max | 0.035 |

| Sulfur, max | 0.035 |

| Silicon, max | 0.25 |

Mechanical Properties of ASTM A192 tubes:

| Tensile Strength, min, ksi [Mpa] | 47 [325] |

| Yield Strength, min, ksi [Mpa] | 26 [180] |

| Elongation in 2 in. or 50mm, min, % | 35 |

| Brinell Hardness Number (WT≥ 0.2in [5.1mm[) | 137HBW |

| Rockwell Hardness Number (WT< 0.2in [5.1mm] ) | 77HRW |

Heat Treatment:

Hot-finished ASTM A192 tubes need not to be heat treated. Cold-finished tubes shall be heat treated after the final cold-finishing at a temperature of 1200°F [650°C] or higher.

Other Tests:

Flattening test——One flattening test shall be made on specimens from each end of two tubes selected from each lot or fraction thereof.

Flaring Test——One flaring test shall be made on specie- men from each end of two tubes selected from each lot or fraction thereof. These tubes shall be selected apart from those used for the flattening test.

Hydrostastic Test——Each tube shall be subjected to the hydrostatic pressure test, or instead of this test, a nondestructive test may be used when specified by the purchaser.

Package:

Wooden box, bundles with plastic paper